Inspection Standard

- Share

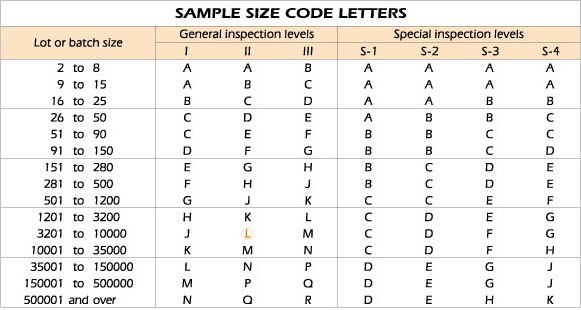

QTS uses the ANSI/ASQ Z1.4-2008 as its sampling standard and acceptable level of quality.

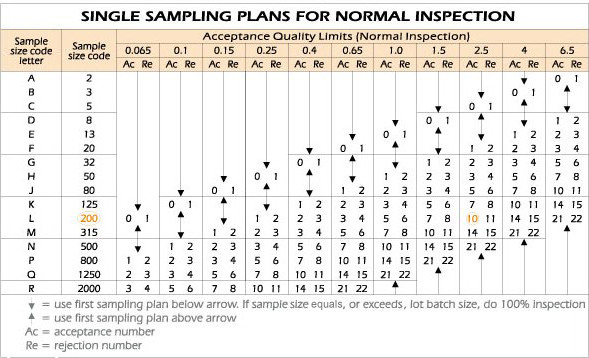

It offers the advantage of clearly defining the number of samples to be inspected from a given lot or consignment. It also suggests the maximum number of defective items allowed in the samples size unless specified by clients. Our default Acceptable Quality Level is Level II.

Defects detected during visual inspections are classified into three categories as follows:

Critical Defect – corresponds to a defect likely to be unsafe for consumers. Our default Critical Defect AQL is Not Allowed.

Major Defect – results in function failures or reduction of product usability or obvious appearance faults which may affect the salability of the product. Our default Major Defect AQL is 2.5.

Minor Defect – doesn't reduce the usability or function of the product, but is beyond the defined quality standard and may reduce the salability of the product. Our default Minor Defect AQL is 4.0.

Clients can also specify what points are Minor, Major or Critical in their own checklists.